Automatic Frozen French Fries Production Line Price

- Capacity:1000 kg/h

- Processing Objects:Fresh potatoes

- Brand:LONGER Machinery

- Warranty Time:12 Months

Features

Frozen french fries production line produced by our factory is specializing in the production and processing of French fries and potato chips. French fries potato chips production line equipment ordering hotline 18595717505, the fries potato chips production line equipment is an economical and practical fries production equipment combining domestic and foreign advanced technology research and development and has developed. Its advanced technology, factory price, reliable quality assurance and perfect after-sales service team provide customers with purchase protection.

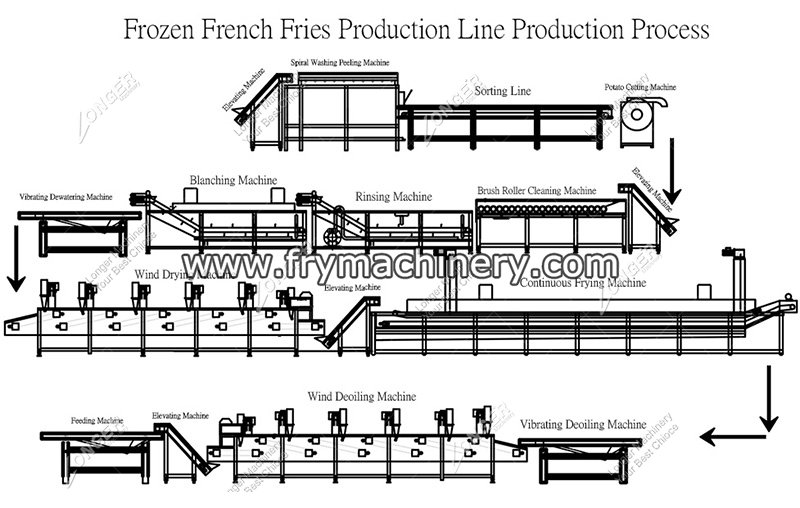

Frozen French fries production and processing processes generally need to go through the following steps:

Lifting and feeding → Potato washing peeling → Potatoes picking → Lifting and feeding → Potato strips cutting → Rinsing → French fries blanching → French fries dehydration → French fries frying → Oil removing → Seasoning → Freezing → Packaging.

The required potato French fries potato chips processing line consists of hoist, potato cleaning peeling machine, potatoes picking line, French fries cutting machine, cleaning blanching line, hot air dehydration, french fries frying line, centrifugal deoiler, flavoring machine, quick freezer, and packing Machine.

Main Functions of Frozen French Fries Production Line Equipment

1. Peeling: Potatoes are first cleaned and peeled by a potato washer and peeler machine.

2. Cutting: The peeled potatoes are cut into French fries by a high-speed cutting machine.

3. Rinsing: Cut the fries into the ozone disinfection washing machine, rinse the surface of the mucus.

4. Blanching: rinse clean fries into the blanching machine for blanching, in order to passivate the oxidase in the fries to prevent deterioration of color, speed up dehydration.

5. vibration water removing: After blanching, the fries into the vibration drain machine to remove excess water.

6. Frying: The French fries after removing water are sent to the fryer for frying treatment by the lifting conveyor.

7. Removing oil (air-dried lifting): The fried French fries are drained after being air-dried and then fed into a seasoning machine.

8. Mixing: The blender has a dip-type seasoning roller, which fully controls the speed of rotation and the material capacity. It is equipped with an automatic powder feeding device that can adjust the size of the powder to be fed and fully mix the fries and seasoning powder.

9. Freezing: Frozen treatment for French fries, easy for transport, can be kept for long time.

10. Weighing and Packaging: The fries that are tasted are sent to the packaging machine for vacuum packaging or ordinary packaging. If necessary, a weighing mechanism can be added.

Working Video of Automatic Frozen French Fries Production Line

More Picture of Automatic Frozen Fries Production Line

Production of conventional French fries production line ranges from 100 kg to 1000 kg per hour. If you want to know the price of automatic french fries production line, please feel free to contact us.

Technical Data

| Equipment Name | Power | Dimension |

| 1. Pre washing Elevator | 0.75 kw/380V/50HZ | 1800*1200*1500mm |

| 2. Pre Washing Machine | 5.1 kw/380V/50HZ | 3000*900*1400mm |

| 3. Elevator | 0.75 kw/380V/50HZ | 2000*1000*1600mm |

| 4. Emery Peeling Machine | 6.05kw/380V/50HZ | 3600*1200*1400 mm |

| 5. Sorting Conveyor | 0.75 kw/380V/50HZ | 5000*1000*950mm |

| 6. Waste Transfer Cart | / | 600*400*500mm |

| 7. Potato Chips Cutting Machine(Two Sets) | 1.1 kw/380V/50HZ | 900*850*900mm |

| 8. Elevator | 0.75 kw/380V/50Hz | 1500*1000*1500mm |

| 9. Impurity Removing Machine | 1.5 kw/380V/50HZ | 2600*1000*1400 mm |

| 10. Rinsing Machine | 3.7 kw/380V/50HZ | 6000*1600*1400mm |

| 11. Blanching Machine | 100 kw/380V/50HZ | 6500*1600*1400mm |

| 12. Vibrating De-watering Machine | 0.25 kw/380V/50HZ | 1800*1500*1300mm |

| 13. Air De-watering Machine | 15 kw | 8000*1600*1600mm |

| 14. Stainless Steel Elevator | 0.75 kw/380V/50HZ | 2000*1500*1350mm |

| 15.French Fries Fryer | 120 kw/380V/50HZ | 8000*1600*2400mm |

| 16. Oil Filting Machine | ||

| 17. Oil Adding Tank | 15 kw/380V/50HZ | 8000*1600*1600mm |

| 18. Vibrating Oil Removing Machine | 0.25 kw/380V/50HZ | 1800*1500*1300mm |

| 19. Air De-oil Line | 12 kw/380V/50HZ | 8000*1600*1600mm |

| 20. Elevator | 0.25 kw/380V/50HZ | 2000*1000*1600mm |

| 21. Deoiling Machine | 0.25kw/380V/50HZ | 20000*3000*3000mm |

| 22. Frozen Tunnel | 300 kw/380V/50HZ | 20000*3000*3000mm |

| 22. Packing Machine | 3 kw/380V/50HZ | 3000*2000*2600mm |

FAQ

Q: I want to know the price of frozen French fries production line?

A: Dear, we have differnet production capacity for selection, from 100 kg/h to 1 ton/h, you can tell ue your specific requirement, we can suggest you suitable model.

Q: Do you have video for french fries making machine?

A: Yes, we have working video, you can leave your email or mobile number here, we can send it to you.

Q: I am new starter, i want to know which project is suitable for me?

A: For your requirement, you can tell us your email, so we can send you project we made before for your selection.

A: Dear, we have differnet production capacity for selection, from 100 kg/h to 1 ton/h, you can tell ue your specific requirement, we can suggest you suitable model.

Q: Do you have video for french fries making machine?

A: Yes, we have working video, you can leave your email or mobile number here, we can send it to you.

Q: I am new starter, i want to know which project is suitable for me?

A: For your requirement, you can tell us your email, so we can send you project we made before for your selection.

Message

Your submitted data will be stored for internal processing and own communication purposes, following existing privacy policies. Your data will not be disclosed to third party!